Understanding E-Glass Cloth and Copper Clad Laminates (CCL)

E-Glass Cloth: The Backbone of PCB Strength

E-glass cloth is a type of fiberglass fabric made from electrical-grade glass fibers. Known for its high strength and excellent electrical insulation, this material is the backbone of PCB structure.

- Composition: E-glass cloth is woven from extremely fine strands of glass, which are treated with specialized coatings to enhance resin adhesion and performance.

- Properties:

- High tensile strength and durability.

- Excellent thermal resistance, essential for high-performance PCBs.

- Superior electrical insulation, preventing signal interference.

- Role in PCB Manufacturing:

E-glass cloth is impregnated with epoxy resin and layered to form the substrate, the structural base of the PCB. Its job is to provide mechanical stability while ensuring the board can withstand heat and electrical stresses.

Copper Clad Laminates (CCL): The Functional Layer

CCL is the material that gives PCBs their conductive properties, enabling electrical signals to flow seamlessly. A CCL is composed of E-glass cloth layers soaked in resin, combined with a thin sheet of copper foil bonded on one or both sides.

Types of CCL:

- Rigid CCL – Used for rigid PCBs found in consumer electronics.

- Flexible CCL – Utilized in flexible PCBs for compact devices like wearables.

Key Properties of CCL:

- Electrical conductivity: Thanks to the copper foil.

- Heat resistance: Crucial for components that generate significant heat.

- Dimensional stability: Ensures consistent performance under mechanical stress.

- Manufacturing Process:

The layers of resin-coated E-glass cloth are stacked and pressed under high temperature and pressure with copper foil. This creates a uniform, durable laminate that forms the conductive base of the PCB.

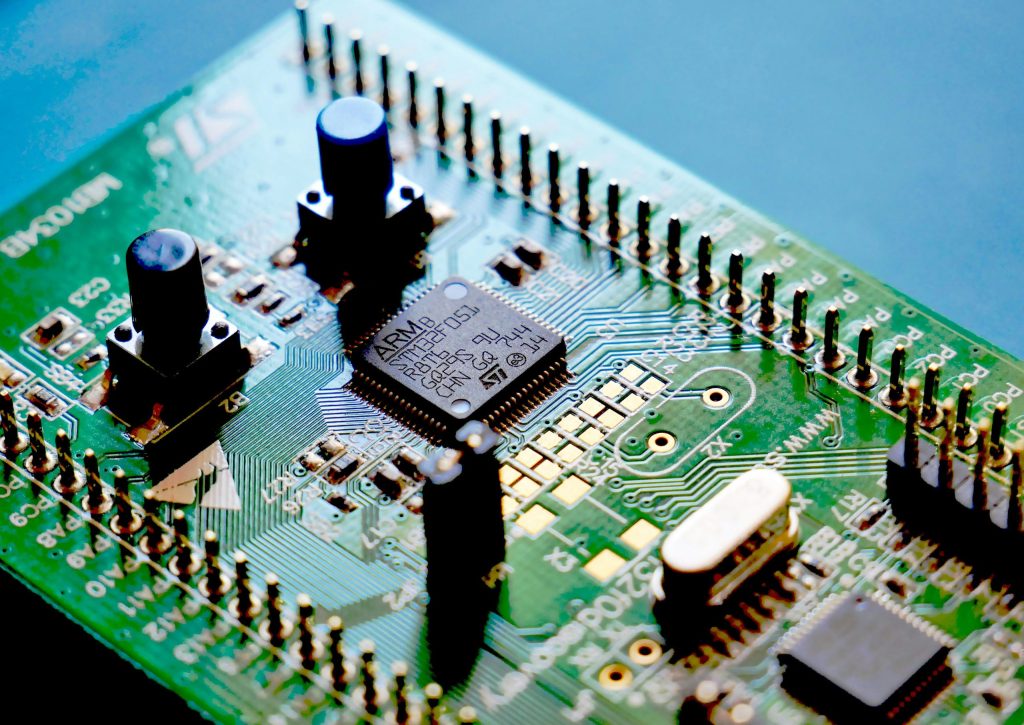

How These Materials Shape a PCB

Once the CCL is created, it undergoes various processes such as drilling, etching, and solder masking to form the circuits and pads. The E-glass cloth provides structural integrity, while the copper layer enables signal transmission. Together, they ensure the PCB is not only functional but also capable of withstanding physical and thermal stresses.

The combination of E-glass cloth and CCL in PCBs highlights the balance between strength and functionality in electronics design. Whether you’re developing cutting-edge devices or ensuring reliability in industrial applications, understanding these materials is key to creating high-quality PCBs.

Feel free to contact us to learn more about our E-glass products and how these products shape a PCB.