Why the industrial pallet washing machine needed?

Pallets are important material handling equipment especially in the logistics industry. However, continuous usage of plastic pallets accumulate dirt, mold and other substances.

This problem was particularly serious in F&B, cloth and high-tech industries. It is very difficult to wash the pallets by man. In addition, there are some dirt which cannot be removed by human hand.

Industrial pallet washer is a machine that automatically performs everything from washing to dehydration and drying, improving the efficiency of pallet washing.

Contact to Professionals↓↓↓

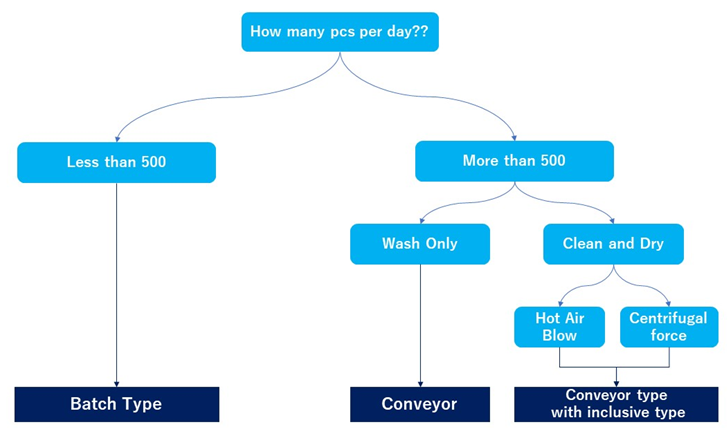

What type of washing machine should we choose?

There are various types to choose, from simple ones that only clean, to large-scale ones such as everything from cleaning to drying. Equipment is selected according to needs, such as equipment installation space and pallet size.

In these days, the needs for industrial washer are high in Thailand. Thus, the variety of such machines are wider than before. For example in the drying stage, there are many types are available in Thailand such as air-blow, vaccuming, NC cleaning, hydrocarbon cleaning and etc.

Example process of industrial purpose are as follows;

De-tiering ➡ Cleaning➡ Dehydration ➡ Hot air drying ➡ Stacking

If less than 500 pallets (depending on the size of the pallets) are washed per day, Batch type is recommended. It is ideal for customers with limited installation space. If more than 500 pallets, conveyor type is strongly recommended. Pallets run on the conveyor, which achieves mass washings.

Want to know more detail of conveyor type of washing machine?

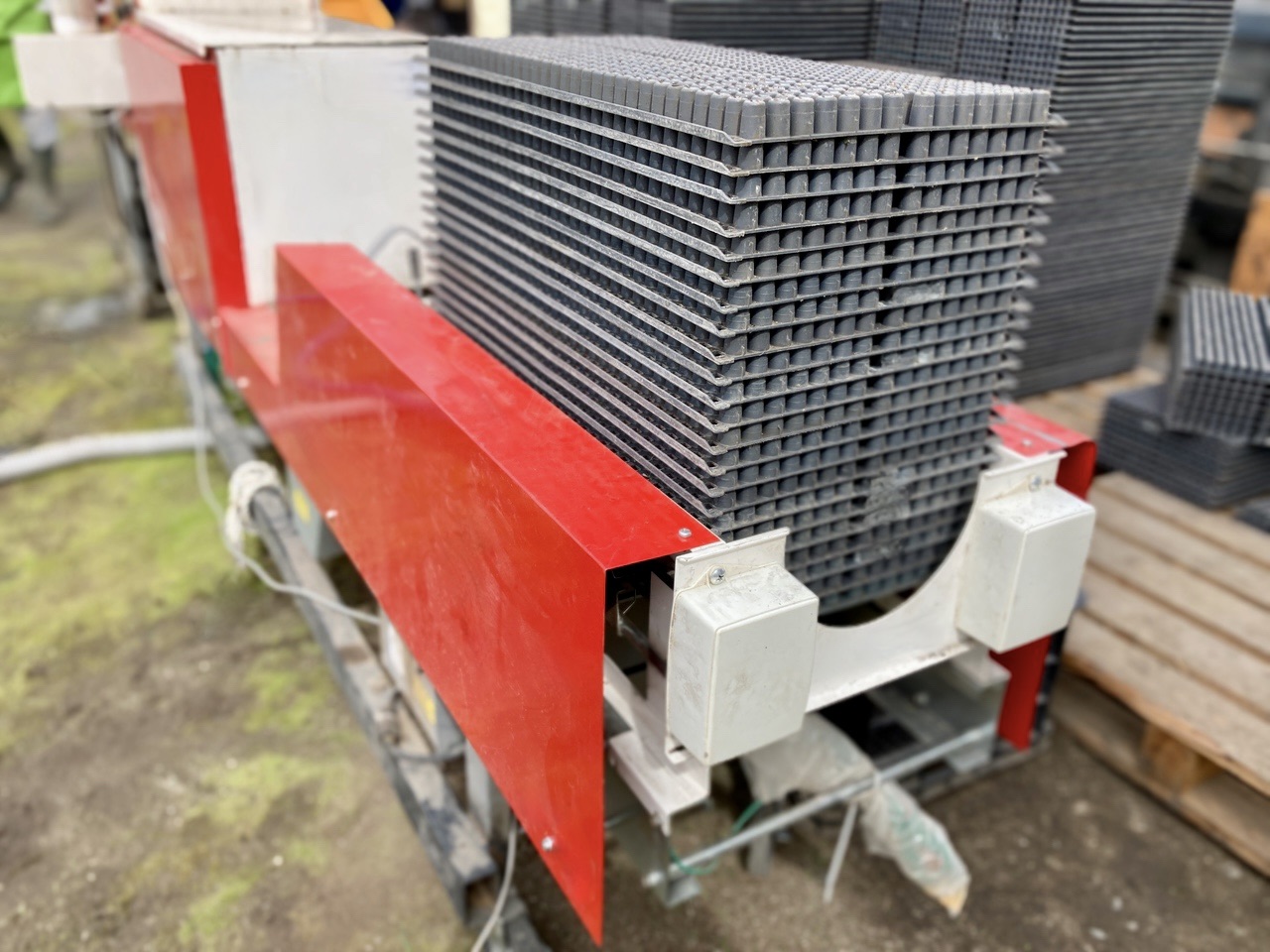

When stacked pallets are placed in a beginning stage of washing machine, the entire pallet is first washed using a low-pressured water method, while a rotating brush removes dirt all around the pallets.

After washing, the pallet is rotated at high speed by centrifugal force to remove water. In the end, an air in high-temperature is blowed, and the remaining water is drained to complete the process.

If you have your space and budget in you mind, please feel free to contact us from below. Our professionals will kindly start from brief meetings or hearings.